Description

Classification:

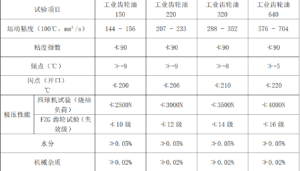

-Classification by viscosity: There are different viscosity grades, such as ISO VG 68, 100, 150, 220, 320, 460, 680, etc. The higher the viscosity, the higher the oil film strength, which is suitable for gear transmission with different loads and speeds.

-Classification by performance: it is divided into ordinary industrial gear oil, medium-load industrial gear oil and heavy-load industrial gear oil. Ordinary industrial gear oil is suitable for gear systems with light load and low speed. Medium-load industrial gear oil is used for medium-load gear transmission; Heavy-duty industrial gear oil can meet the harsh working conditions of high load, high speed and impact load.

Performance characteristics:

-Good extreme pressure and wear resistance: With the addition of extreme pressure and wear resistance additives, a protective film can be formed on the gear surface under high load to prevent wear, abrasion and gluing, and prolong the service life of the gear.

-High viscosity index: the viscosity changes little with temperature, and it can maintain stable lubrication performance at different working temperatures.

-Anti-oxidation stability: it can resist oxidation, reduce the generation of oxides such as sludge and paint film, and ensure the long-term stability of oil products.

-Foam resistance: it can quickly eliminate foam and avoid problems such as poor lubrication, rising oil temperature and power loss caused by foam.

-Emulsification resistance: When it comes into contact with water, it can quickly separate water, prevent the oil from emulsifying and deteriorating, and affect the lubrication effect.