Description

GS-FAA reciprocating air compressor oil is compounded with deeply refined mineral oil and various additives such as anti-oxidation, anti-wear, anti-rust and cleaning.

Working principle:

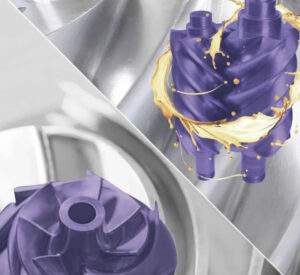

The reciprocating air compressor compresses air through the reciprocating motion of the piston in the cylinder. Air compressor oil plays a role in lubricating moving parts such as piston, cylinder wall, crankshaft and connecting rod, reducing friction and wear, and also plays a role in sealing, cooling and rust prevention.

Performance requirements:

-Good lubricity: It can form a firm oil film on the metal surface under the conditions of high pressure, high temperature and high load to ensure good lubrication between moving parts, reduce friction resistance and reduce wear.

-High flash point: the flash point is generally required to be higher, usually above 200℃, to ensure that it is not easy to burn in high temperature environment and to ensure safe use.

-Appropriate viscosity: According to the working conditions and requirements of the compressor, choose the oil with appropriate viscosity. Generally speaking, compressors with high working pressure and high temperature need to use oil with high viscosity; On the contrary, oil with lower viscosity can be used.

-Oxidation resistance: under the condition of high temperature and contact with air, it is not easy to be oxidized and deteriorated, which can effectively inhibit the generation of harmful substances such as sludge and carbon deposit, prolong the service life of oil products and keep the compressor clean.

-Cleanliness and dispersibility: It can disperse impurities such as wear particles and dust generated during the operation of the compressor in the oil to prevent them from being deposited on the surface of parts, which will affect the normal operation of the compressor.

Application scenario:

It is widely used in various occasions where compressed air is needed, such as mining, metallurgy, machinery manufacturing, construction, chemical industry and so on. In some fields that require high compressed air quality, such as electronics, food, medicine and other industries, it is also necessary to use reciprocating air compressor oil that has been specially treated and meets the relevant hygiene standards.