Description

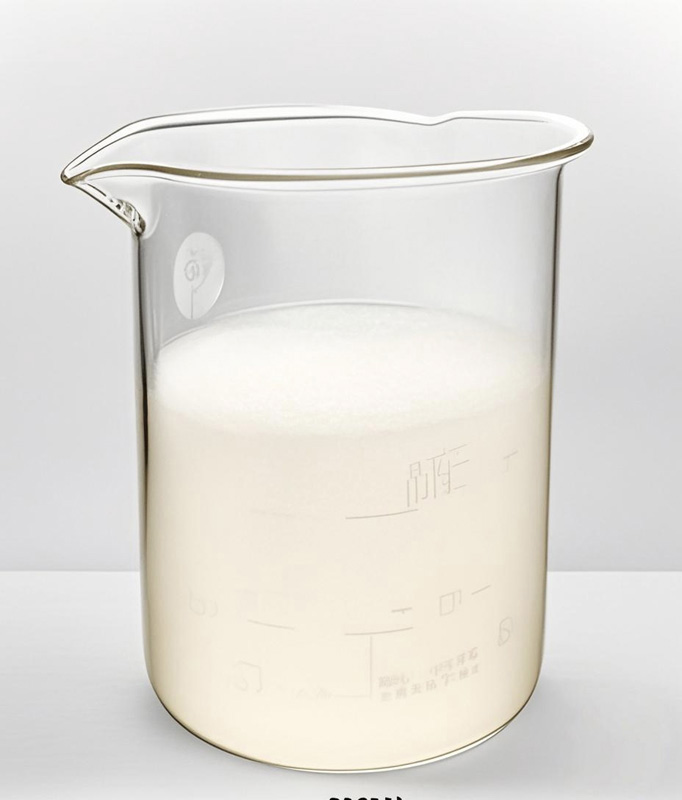

GS-LU11 antirust emulsified cutting fluid is a functional liquid widely used in metal cutting, which is composed of mineral oil, emulsifier, antirust agent, lubricant, extreme pressure additive, preservative and other components. These ingredients are mixed together through a specific formula and process to form a stable emulsion. In appearance, the diluted antirust emulsified cutting fluid usually appears milky white or translucent.

Function:

-Lubrication function: it can form a lubricating film between the tool and the workpiece and between the tool and the chip, reduce the friction coefficient, reduce the tool wear, improve the quality of the machined surface and make the cutting process smoother.

-Cooling function: quickly absorb and take away the heat generated in the cutting process, prevent the workpiece and tool from being deformed or damaged due to overheating, ensure the machining accuracy and prolong the service life of the tool.

-Anti-rust function: It contains anti-rust agent, which can form a protective film on the metal surface, isolate air and moisture, and effectively prevent workpieces, tools and machine tools from rusting, especially suitable for wet environment or short-term anti-rust processing.

-Cleaning function: With the help of emulsifier, it has good cleaning performance, which can quickly wash away chips, abrasive chips and other impurities, keep the machining area clean, and prevent impurities from scratching the surface of the workpiece or affecting the cutting performance of the tool.

Scope of application:

Suitable for cutting a variety of metal materials, such as steel, iron, copper, aluminum and their alloys. It can be used in turning, milling, drilling, boring, grinding and other cutting processes, which can not only meet the requirements of ordinary machining, but also play a role in some occasions with high requirements on rust prevention performance and machining accuracy.

Precautions for use:

-Maintenance: Regularly test the concentration, pH value, antirust performance and other indicators of cutting fluid, and replenish the stock solution and water in time to maintain its stable performance. At the same time, attention should be paid to removing chips and impurities from the liquid tank to prevent bacteria from breeding.

-storage: it should be stored in a cool, dry and well-ventilated place, avoiding direct sunlight and high temperature environment to prevent cutting fluid from deteriorating.