Description

Copper-aluminum cutting oil is a lubricating oil specially designed for cutting copper, aluminum and their alloys.

Composition:

-Base oil: mostly mineral oil or synthetic oil. Mineral oil is economical and practical; Synthetic oil has good performance, oxidation resistance and low temperature fluidity.

-Oily additives: such as animal and vegetable fats and fatty acids, etc., enhance the oil film adsorption, improve the lubrication effect and reduce the friction and wear between the tool and the workpiece.

-Anti-corrosion additives: prevent copper and aluminum from corrosion and discoloration due to contact with cutting oil or external environment during processing, and ensure the surface quality of workpieces.

-Antioxidant: Inhibit oil oxidation, prolong service life, maintain stable performance, and avoid the influence of sludge generated by oxidation on processing.

–Defoamer: reduce the foam generated by stirring during processing, and ensure the normal circulation and use effect of cutting oil.

Performance characteristics:

-Good lubricity: it can form a firm lubricating film on the surface of the tool and the workpiece, reduce the friction coefficient, cutting force, tool wear and improve the surface smoothness and machining accuracy of the workpiece.

-Excellent coolability: quickly take away cutting heat, reduce the temperature in the cutting area, prevent the workpiece from being deformed due to heat, avoid the hardness of the tool from decreasing due to high-temperature annealing, and ensure the machining accuracy and tool life.

-Strong corrosion resistance: contains special corrosion inhibitor additives to prevent copper and aluminum workpieces from corrosion and discoloration during processing and storage. For example, when processing aluminum alloy, white rust on the surface can be avoided.

-Good stability: the chemical properties are stable, and it is not easy to react with copper and aluminum metals, thus ensuring the stability of the processing process.

-Low oil mist and odor: some products have less oil mist and light odor during processing, which improves the working environment of the workshop and ensures the health of operators.

Scope of application:

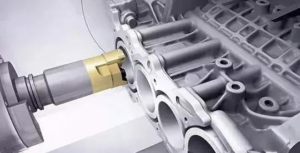

Used for various cutting processes of copper, aluminum and their alloys, such as turning, milling, drilling, boring, tapping and sawing. It covers the processing scenes of precision electronic aluminum parts, copper-aluminum profiles, copper-aluminum castings, etc., and is especially suitable for processing occasions that require high surface quality and precision of workpieces and are not suitable for water-based cutting fluids.

Precautions for use:

Appropriate copper-aluminum cutting oil should be selected according to specific processing requirements, equipment conditions and workpiece materials. At the same time, we should pay attention to the viscosity, dosage and replacement cycle of cutting oil to achieve the best effect.