Description

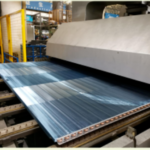

Fin punching oil is a volatile punching oil specially designed for punching and shearing air-conditioner cooling fins. It is composed of special extreme pressure additives and deeply refined volatile solvents. It has excellent volatility, lubricating and cooling functions, no trace of oil after volatilization, no oil on the surface of products, good hydrophilicity and no corrosion to aluminum and non-ferrous metals.

Usually refined mineral oil or synthetic oil is used as base oil, and various additives are added, such as extreme pressure antiwear agent, oiliness agent, antioxidant, antirust agent, etc. These additives can make stamping oil play a good role in lubrication, cooling and protection during high temperature and high pressure stamping.

Working principle:

In the process of fin stamping, fin stamping oil forms a uniform oil film on the surface of die and metal material. This oil film can reduce the friction coefficient between the die and the material, reduce the friction force and make the stamping process smoother. At the same time, it can effectively take away the heat generated in the stamping process, play a cooling role, prevent the die and the material from being damaged or deformed due to overheating, and also form a protective film on the metal surface to prevent rust and corrosion.

Features:

Good extreme pressure performance: it can keep the integrity of oil film in high pressure stamping, prevent dry friction between die and material, reduce die wear, and improve the machining accuracy and surface quality of fins.

Excellent lubricity: the material can be formed smoothly in the die during stamping, which reduces the risk of material strain and tear, and improves production efficiency and product qualification rate.

Good cooling performance: quickly dissipate heat, effectively reduce the temperature of mold and workpiece, prolong the service life of mold, and reduce machining errors caused by thermal deformation.

Easy to clean: the stamping oil left on the surface of the stamped workpiece is easy to clean, and will not affect the subsequent processing procedures, such as spraying and welding.

Good antirust performance: it can form an antirust protective film on the metal surface to prevent the fins from rusting during storage and transportation.

Application field:

It is mainly used for stamping fins in refrigeration equipment industries such as air conditioners and refrigerators. These fins are usually made of metal materials such as aluminum or copper, and are formed into specific shapes and structures by stamping process to increase the heat dissipation area and improve the heat exchange efficiency of refrigeration equipment.